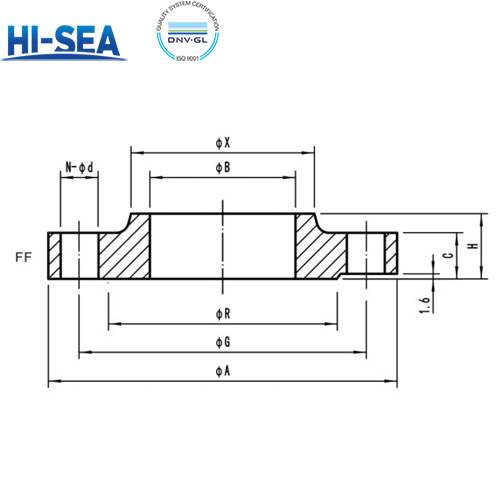

150Lbs Sliding Flange

150Lbs sliding flange is a commonly used piping connector, mainly used in industrial piping systems, especially in occasions that require frequent disassembly and installation.

Overview

Installation steps:

1、Ensure that the pipe and flange are clean and free of oil and impurities.

2、Sleeve the flange on the pipe and make sure that the sealing surface is close to the end face of the pipe.

3、Use the bolts to connect the flange with the pipeline, tighten the bolts in a cross-diagonal order to ensure that the connection is uniformly tight and avoid leakage.

Features:

Pressure rating: suitable for piping systems with working pressure not exceeding 150Lbs.

Material: usually made of carbon steel, stainless steel and other materials, with corrosion resistance, high temperature resistance and pressure resistance.

Design standard: comply with ANSI B16.5 standard, size, screw hole arrangement, flange thickness, etc. are in line with the standard requirements.

Installation: Slip-on design allows for smooth and hassle-free installation with a simple bolted connection.

Application Scenario: Suitable for various industrial applications.

Outside diameter of pipe | ANSIB16.5 | ||||||||||

150Lbs | |||||||||||

θD | θA | H | C | θX | θR | θB | Drilling | Theo. | |||

θG | N | θd | weight | ||||||||

Nominal | actual | mm | mm | mm | mm | mm | mm | mm | bolt | mm | Kg/ piece |

inch | mm | holes | |||||||||

0.5 | 20 | 90 | 15.9 | 11.1 | 30.2 | 34.9 | 20.2 | 60.3 | 4 | 15.9 | 0.9 |

0.75 | 25 | 100 | 15.9 | 12.7 | 38.1 | 42.9 | 25.2 | 69.8 | 4 | 15.9 | 1.1 |

1 | 30 | 110 | 17.5 | 14.3 | 49.2 | 50.8 | 30.2 | 79.4 | 4 | 15.9 | 1.2 |

1.25 | 38 | 115 | 20.6 | 15.9 | 58.7 | 63.5 | 38.3 | 88.9 | 4 | 15.9 | 1.5 |

1.5 | 44.5 | 125 | 22.2 | 17.5 | 65.1 | 73 | 44.8 | 98.4 | 4 | 15.9 | 1.6 |

2 | 57 | 150 | 25.4 | 19.1 | 77.8 | 92.1 | 57.4 | 120.6 | 4 | 19 | 2.7 |

2.5 | 76.1 | 180 | 28.6 | 22.2 | 90.5 | 104.8 | 76.5 | 139.7 | 4 | 19 | 4.1 |

3 | 88.9 | 190 | 30.2 | 23.8 | 107.9 | 127 | 89.4 | 152.4 | 4 | 19 | 4.1 |

4 | 108 | 230 | 33.3 | 23.8 | 134.9 | 157.2 | 108.5 | 190.5 | 8 | 19 | 7 |

5 | 133 | 255 | 36.5 | 23.8 | 163.5 | 185.7 | 133.8 | 215.9 | 8 | 22.2 | 8 |

6 | 159 | 280 | 39.7 | 25.4 | 192.1 | 215.9 | 159.8 | 241.3 | 8 | 22.2 | 9.9 |

8 | 219.1 | 345 | 44.4 | 28.6 | 246.1 | 269.9 | 220.3 | 298.4 | 8 | 22.2 | 15.7 |

10 | 267 | 405 | 49.2 | 30.2 | 304.8 | 323.8 | 268.4 | 361.9 | 12 | 25.4 | 22.8 |

12 | 323.9 | 485 | 55.6 | 31.8 | 365.1 | 381 | 325.4 | 431.8 | 12 | 25.4 | 33.9 |

14 | 368 | 535 | 57.1 | 34.9 | 400 | 425.1 | 369.5 | 476.2 | 12 | 28.6 | 45 |

16 | 419.1 | 595 | 63.5 | 36.5 | 457.2 | 482.6 | 420.5 | 539.7 | 16 | 28.6 | 49 |

18 | 457.2 | 635 | 68.3 | 39.7 | 504.8 | 533.4 | 458.7 | 577.8 | 16 | 31.7 | 63 |

20 | 508 | 700 | 73 | 42.9 | 558.8 | 584.2 | 509.5 | 635 | 20 | 31.7 | 81.5 |

24 | 610 | 815 | 82.5 | 47.6 | 663.6 | 692.1 | 611.5 | 749.3 | 20 | 34.9 | 105.55 |