10-CB Serial Dredging Cutter Teeth

The 10-CB serial dredging cutter teeth are specially designed for use in dredging applications to effectively cut through and remove sediment, debris, and other materials from bodies of water. These cutter teeth are made from high-quality materials such as alloy steel or tungsten carbide, which ensures durability and long-lasting performance in harsh underwater conditions.

The 10-CB serial dredging cutter teeth feature a sharp cutting edge that can easily penetrate and break up tough materials, allowing for efficient dredging operations. These cutter teeth are available in various sizes and configurations to suit different dredging equipment and applications.

High-quality construction: Made from durable materials to withstand the rigors of dredging operations.

Sharp cutting edge: Ensures efficient cutting and removal of sediment and debris.

Various sizes and configurations: Available to fit different dredging equipment and applications.

Long-lasting performance: Designed to provide reliable performance over an extended period of time.

Overview

The 10-CB serial dredging cutter teeth are specifically designed for use in dredging applications where high performance and durability are essential. These cutter teeth are typically used in cutter suction dredgers, which are used to remove sediment and debris from bodies of water such as rivers, lakes, and harbors.

The application of the 10-CB serial dredging cutter teeth is crucial in ensuring the success of dredging projects. These cutter teeth are typically attached to the cutter head of the dredging equipment and are responsible for breaking up and loosening the material to be dredged. By using high-quality cutter teeth such as the 10-CB serial dredging cutter teeth, operators can ensure that their dredging operations are efficient, cost-effective, and environmentally friendly.

Features

The unique male teeth design and easy locking system.

The unique alloy, in which a composite insert is placed to reinforce the working tip of the tooth.

Self sharpening of the tooth, better ground penetration, increased production.

Versatile design: The teeth are designed to fit a variety of dredging cutter heads, making them suitable for a wide range of dredging applications.

Wear-resistant coating: The teeth are coated with a wear-resistant material to prevent premature wear and tear, increasing their lifespan.

Increased lifetime, decreased frequency and duration of maintenance.

Corrosion-resistant: The teeth are resistant to corrosion, making them suitable for use in harsh marine environments.

Cost-effective: The teeth are designed to offer a cost-effective solution for dredging operations, providing long-lasting performance at a competitive price.

Our dedicated heat treatment process finally extracts the maximum mechanical performance out of the carefully casted and forged complex alloys.

Customizable options: The teeth can be customized to meet specific dredging requirements, such as different sizes and shapes.

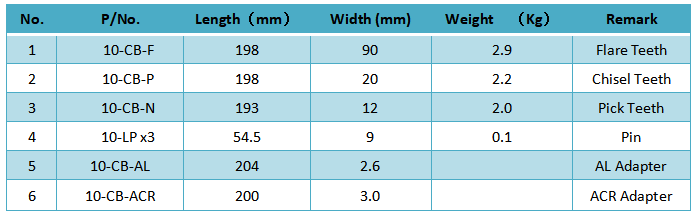

Technical Parameters of 10-CB Serial Dredging Cutter Teeth

10-CB Serial Dredging Cutter Teeth in Factory